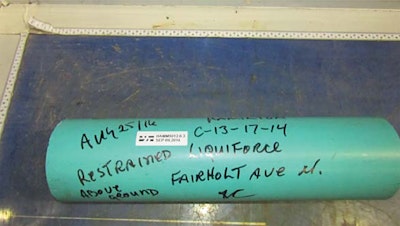

Workers create a lateral sample on the job site using a thermocouple to monitor the temperature and ensure a comparable proxy.

As the popularity of trenchless lateral rehabilitation continues to grow, so does the need for cost-effective quality-control measures for CIPP repairs on the private side.

Like many other cities throughout North America, the city of Hamilton, Ontario, has found a proactive rehab program for sewer laterals is preferable to costly and reactive opencut repairs. The city first developed its lateral rehabilitation program in 2008, has renewed its contract multiple times and, as of...