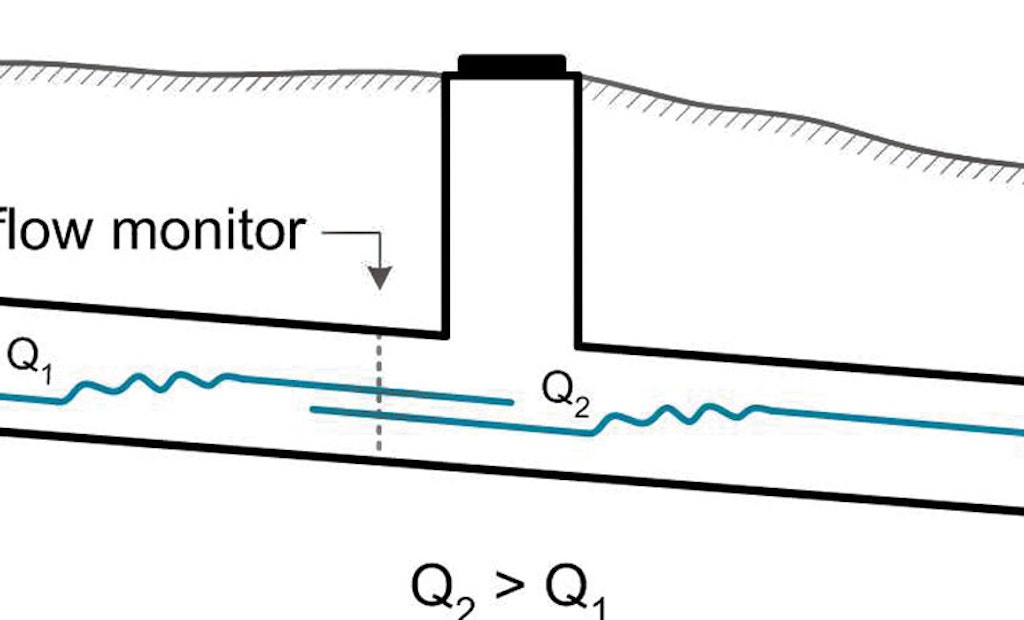

FIGURE 6: A hydraulic jump occurs when flow transitions from supercritical to subcritical flow. Supercritical conditions are observed on the upstream side of the jump, and subcritical conditions are observed on the downstream side of the jump.

We started this series of articles to provide guidance based upon over 40 years of flow monitoring experience. It is also an aid to rainfall-dependent inflow and infiltration study practitioners so that they may avoid project stumbling blocks that have been observed over time.

In the last article, we discussed the importance of focusing basin sizes to provide maximum granularity in identifying problem areas in the collections system. By reducing basin footages, a targeted...