CONTRACTOR CHOOSES STEEL MANHOLE RISERS FOR MULTIPLE PROJECTS

PROBLEM:

Founded in 1969, Herzog Contracting is a giant, with six divisions spread across rail, waste management and roadway construction and maintenance. In 2014, Herzog began implementing a roadway contracting innovation from another firm, the Pivoted Turnbuckle Manhole Riser from American Highway Products.

“We’d been using cast iron risers exclusively to raise manholes to grade,” says Bryan Jones, vice president of project delivery in Herzog’s Heavy Highway Division. “They were effective in many ways, but inventory was a persistent challenge. We perform work for a lot of different municipalities, all with differently sized manholes, and it was difficult to keep every size of riser we may need in inventory.”

SOLUTION:

For Jones, the chief advantage of the risers was adjustability. They’re sturdy, flexible rings made of galvanized steel, are easy to set into original utility rims and the pivoted turnbuckle enables fast adjustment to securely fit variously sized manholes. “We first used AHP manhole risers for Wathena, Kansas. I ordered almost 100 risers for that project — we knew from the start they would be a great fit for our operations.”

Result: Since then, Herzog has installed over 1,000 Pivoted Turnbuckle Manhole Risers, keeps a year’s inventory on hand, and has not had any failures to date. Summing up, Jones says, “The AHP risers are a great asset to our operations, and they’ve been incredible to work with over the years.” 888-272-2397; www.ahp1.com

EPOXY LINER PROVIDES A SPEEDY RETURN TO SERVICE

PROBLEM:

Dillsburg Area Authority in Pennsylvania was searching for a coating solution that would provide superior structural integrity with a quick return to service for three 5-foot diameter by 8-foot deep manholes. “Time was essential due to the need for traffic control and the necessity to return the manholes to service quickly,” says Drew Frank, service coordinator of PSI Pumping Solutions’ service department.

SOLUTION:

The product solution was found in Epoxytec’s flagship product, CPP Trowel-Liner (also available in sprayable form, known as CPP Sprayliner). This two-component epoxy compound is moisture tolerant and composed of 100% solids. Blended with reinforcing agents and various fibers, it creates reinforcement as a fiber-reinforced-polymer with high flexural properties once cured. The characteristics of this product provided the desired strength and necessary rapid return to service needed.

Result: “We were very impressed with the speed of product delivery, and with the exceptional availability of support from our representatives at Atlantic Coating Consultants (Tnemec/Epoxytec),” says Clint Carey, service manager at PSI Pumping Solutions. The combination of the liner product and PSI’s knowledgeable staff gave Dillsburg Area Authority the solution they were looking for and an upgrade in the condition of the manholes. 877-463-7699; www.epoxytec.com

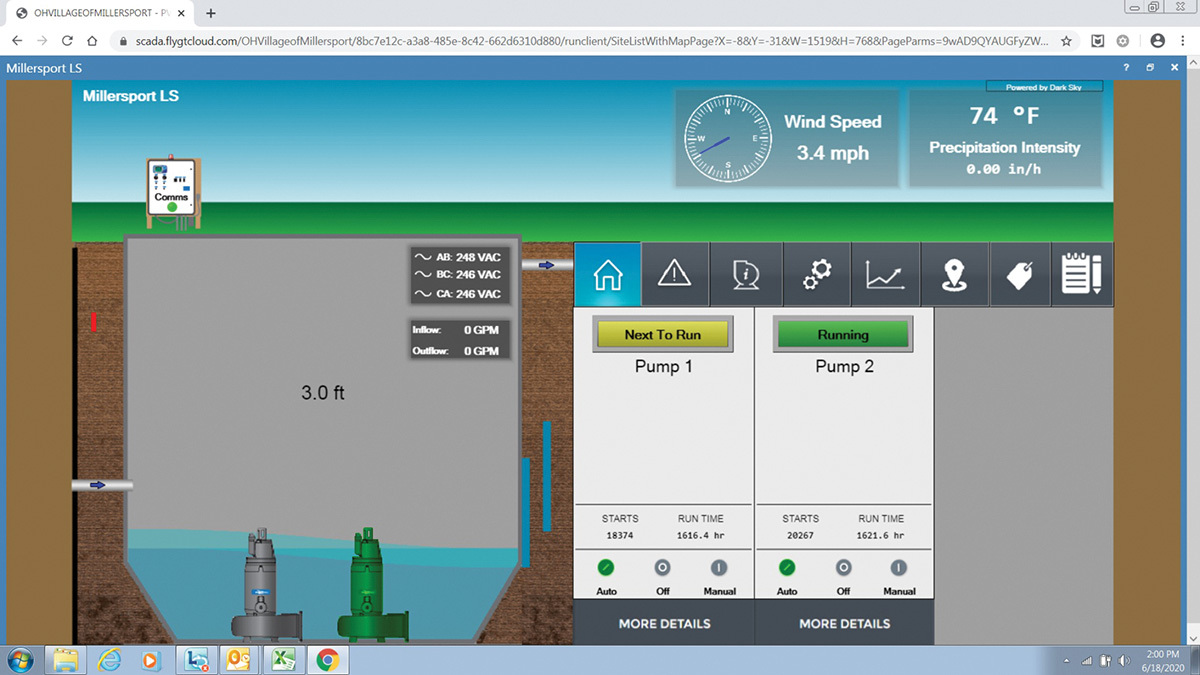

UTILITY UPGRADES OUTDATED LIFT STATION

PROBLEM:

The Terrace Street Lift Station is the main lift station for the village of Millersport, Ohio. Two surface pumps handled daily operation. During rainstorms, two 30 hp submersible pumps took over. By 2017, the surface pumps had reached their end-of-life. Flow went through the surface pump wet well first and overflowed into the submersible pump wet well. But debris settled in the wet well and plugged the surface pumps during rain events. Frequent unclogging decreased pump efficiency and increased maintenance costs. Additionally, the village didn’t grow as expected, and the 30 hp submersible pumps were oversized, causing inflow to the facility. That resulted in increased treatment costs and added capacity to the collection system.

SOLUTION:

The village engaged Xylem to engineer a complete design/build solution. Working with Stutske Construction, they designed a turnkey solution for the lift station upgrade. Stutske found flow issues on Terrace Street and the nearby canal. Because all sewage flows toward the Terrace Street Lift Station, the infiltration caused backflow issues during heavy rains. The upgrade included installing two 10 hp Flygt N-Technology submersible pumps in the existing wet well. The pumps are controlled by two Aquavar IPC variable-frequency drives, water level control float sensors and a MultiSmart controller.

Result: Since completion, pump clogging has ceased, and energy consumption has dropped. In addition, with the installation of Flygt Cloud SCADA, they can remotely control the pumps to eliminate wastewater spills. 855-995-4261; www.xylem.com/pumping

CAMERA BOOSTS EFFICIENCY FOR CITY’S STORMWATER UTILITY DIVISION

PROBLEM:

The city of Wichita, Kansas’s Stormwater Utility Division was struggling to efficiently assess its collection system and combat problems like pipe defects and I&I with its singular CCTV van. Inspecting the city’s 1,400 miles of storm conduit is no small task, and in 2018, it was estimated it would take the division 40 years to complete the full system assessment.

SOLUTION:

The division decided that new equipment was the way forward, and discovered the Quickview airHD zoom assessment camera from Envirosight, which can look as far as 400 feet down a line to capture rapid, high-quality footage of pipe condition. The team was so impressed by Quickview’s zoom capabilities that it quickly invested in four systems.

Result: The team started to see results immediately. With Quickview, the division can get eyes underground fast. Determining sources of I&I, corroded pipe in need of repair and more is now finally within its grasp. “Honestly, we were surprised how much it instantly changed the way we go about business, for the good,” says Darrin Deutscher, general supervisor II for the division. “I didn’t expect it to give us all the things it gave us. Now, instead of CCTVing everything, we use these zoom cameras.” Deutscher expects the system assessment to take around five years – just a fraction of the previous estimate. The insights that the system offers also help with pipe rehabilitation and budget planning. 866-936-8476; www.envirosight.com

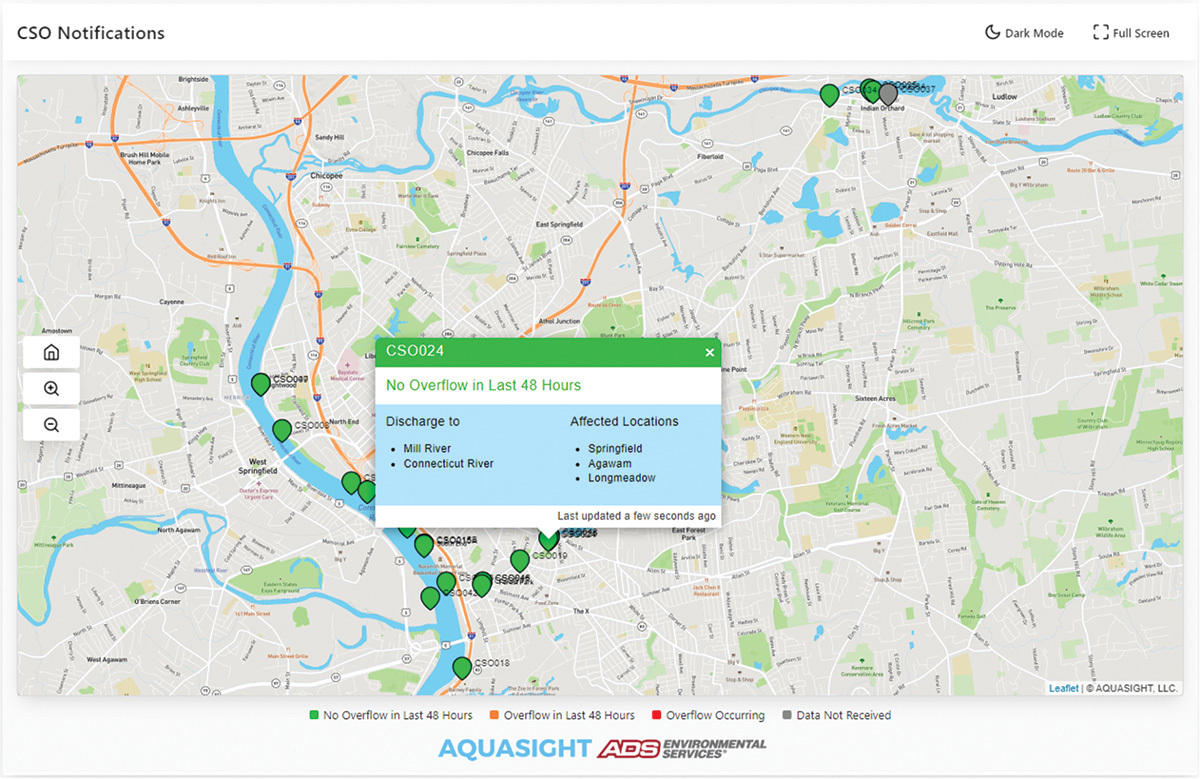

CITY ACQUIRES SEAMLESS CSO REGULATORY REPORTING

PROBLEM:

Cities in Massachusetts are experiencing new pressures for reporting combined sewer overflows. Typically triggered by wet weather, overflow reporting requirements have taken on a new dimension. The public must be notified of an overflow on a public website within two hours of activation. Additionally, individuals may opt in to receive email notifications of the events. Notifications must be in both English and other major languages of each city. The city of Springfield, Massachusetts, and its contract operations partner Veolia Water needed a solution that would not require significant resources.

SOLUTION:

ADS Environmental Services partnered with Aquasight to deliver a tailored, easy-to-deploy metering and public reporting system. The ADS flowmeter system and PRISM flow metering software were coupled with the Aquasight ACE Intelligent Sewer Solution in fewer than eight weeks. ACE has many built in capabilities, one of which being the CSO feature which integrates ADS flow monitoring devices with Aquasight’s powerful GIS centric, analytical, reporting and email notification feature.

Result: The city now has an automated tool for seamless reporting, including discharge location, time of discharge, estimated volume, time of discharge end, affected water bodies and affected communities. With the flow metering and public reporting system, Springfield can now seamlessly and easily meet regulatory requirements while the public has a new awareness of overflow events, promoting greater safety. 800-633-7246; www.adsenv.com

ROBOTIC CAMERA WITH FLOATING MODULE HELPS INSPECT OVERFLOWING STORM DRAINS

PROBLEM:

Municipal utility workers experienced troubles inspecting overflowing storm drains after heavy rains in a Midwestern city. The main issue that complicated their survey was the significant amount of soil sediments in the bottom and the high-water level, which made using a regular pipe crawler impossible. The crawler got stuck a few feet into the drain.

SOLUTION:

The utility purchased a SIGMA HD robotic camera mounted on the W350 floating module from Fiberscope.net by MEDIT. The unit is specially designed to inspect larger diameter pipes with high water levels.

This module lets the camera float on top of the water and transmits a live video via the attached tether. The HD camera head can still fully pan-tilt-zoom, and the extremely bright LED illumination provides image quality even in completely dark drains. The boat is also protected against accidentally flipping.

Result: The module was sent down the storm line and picked up at the exit. The average floating speed during this inspection was 240 feet per 20 minutes. This allowed the crew to inspect multiple overflow drains efficiently in a relatively short period of time. 877-613-2210; www.fiberscope.net

I&I ANALYSIS TOOL BRINGS 25 TO 50% PRODUCTIVITY GAINS

PROBLEM:

Since its inception, New Jersey-based CSL Services has logged over 2 million-meter days and established itself as one of the leading flow monitoring and pipeline inspection companies in the United States. Its flow studies typically last from 60 days to six months and can use as many as 50 or more flowmeters. The company needed a tool for its engineers to become more efficient in generating analyses from these studies to avoid manually loading I&I data into Excel spreadsheet templates.

SOLUTION:

Bill Dawson, vice president of CSL Services, discovered the FlowWorks I&I Analysis Tool from Carl Data Solutions. The feature set includes an automated dry weather pattern generator and an automated storm event group finder for faster, more accurate analysis. An RDII (rainfall-derived inflow and infiltration) chart provides a powerful, quantitative view of the collection system’s wet weather response. A correlation report provides a linear regression between rainfall and RDII to assist in forecasting wet weather impacts on the collection system. With the tool, Dawson’s engineers can export both graphs and the underlying data to include into a report.

Result: “This is a competitive differentiator for us,” Dawson says. “FlowWorks has allowed our engineers to become much more efficient in generating these I&I analyses.” He added that his engineering time on flow monitoring studies has decreased by an “average of 25% with the FlowWorks I&I Analysis Tool, and up to 50% on larger projects involving 20 or more meters.” 206-859-6999; www.flowworks.com

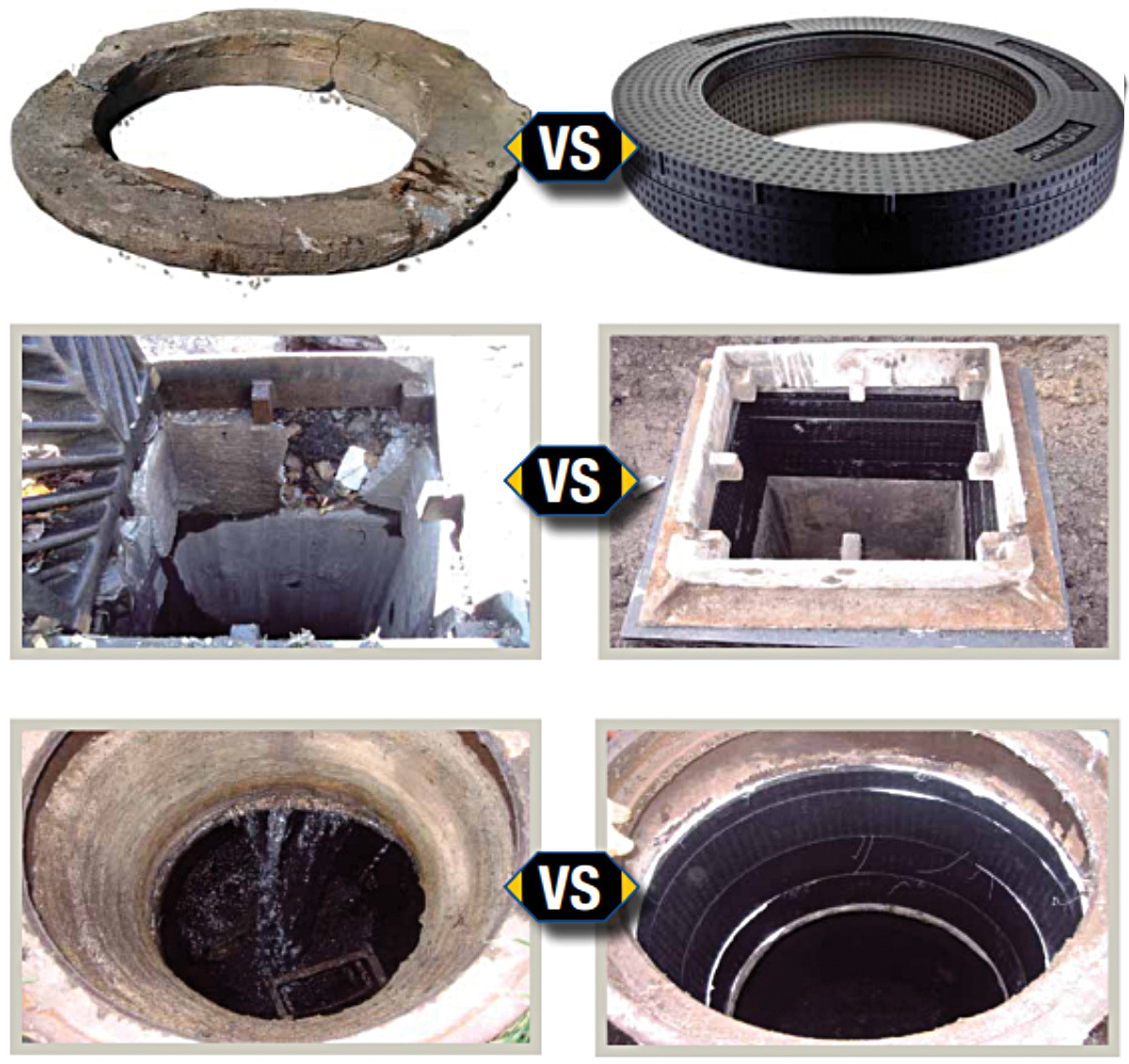

SEVERE INFILTRATION STOPPED AFTER INSTALLING MANHOLE ADJUSTMENT SYSTEM

PROBLEM:

In late 2009, a south-central Wisconsin municipality identified a manhole with a severe infiltration problem needing repair. The water was coming from an extremely high groundwater table due to an underground aquifer and was leaking through the joint between the concrete rings and precast manhole cone. This single manhole was contributing in excess of 20,000 gallons of clear water every day all year long. The manhole was excavated, the frame and existing 20 inches of cracked and corroded precast concrete grade rings were removed exposing the top of the manhole cone.

SOLUTION:

Cretex Specialty Products had just introduced PRO-RING, a lightweight manhole grade adjustment system made from expanded polypropylene, and it was chosen for this repair as a trial. EPP is a high strength, solid lightweight plastic, making it suitable to replace traditional construction methods using masonry materials. This system is watertight, fast, safe and cost effective, with one worker being able to complete an entire adjustment in just minutes. It doesn’t require any additional coatings or seals. It is also resistant to salt, road chemicals and sewer acids. The solid core design system ensures that it won’t freeze and crack due to water infiltration or heavy loads during winter. It meets DOT requirements, and is in widespread use throughout public works departments in the United States, Canada and Australia.

Result: Since the installation was completed more than 12 years ago, this manhole has remained watertight, saving the municipality more than $430,000 ($36,000/year) in treatment costs. Subsequent inspections through the years indicate the rings will last many more decades. 800-345-3764; www.cretexseals.com